Mastering Tesla Minor Collision Repair and Realignment Techniques

Tesla minor collision repair involves meticulous processes by trained technicians. Inspection identi…….

In the rapidly evolving landscape of automotive maintenance, Tesla minor collision repair has emerged as a game-changer. This specialized field focuses on the precise and efficient restoration of Tesla vehicles following minor accidents or damage. As electric vehicle (EV) technology continues to advance, understanding the intricacies of Tesla minor collision repair becomes increasingly vital for both industry professionals and car owners.

This comprehensive article aims to provide an in-depth exploration of this niche yet critical segment of the automotive sector. We will dissect its definition, global reach, economic implications, technological innovations, regulatory framework, challenges, successful implementations, and future prospects. By delving into these aspects, readers will gain valuable insights into the world of Tesla minor collision repair and its potential to shape the future of vehicle servicing.

Definition:

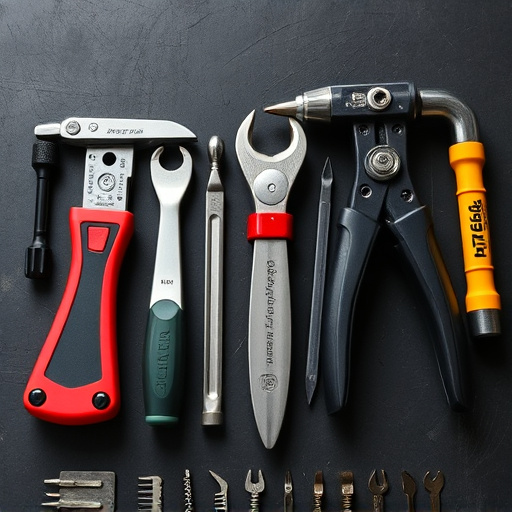

Tesla minor collision repair refers to the process of repairing and restoring Tesla vehicles that have sustained minimal to moderate damage in accidents or other incidents. It involves skilled techniques, specialized tools, and a deep understanding of electric vehicle (EV) systems to ensure the safety, efficiency, and longevity of the vehicle.

Key Components:

Assessments and Safety Checks: Following a collision, a thorough inspection is conducted to identify damage, assess structural integrity, and verify the safety of the vehicle for repair. This includes checking for frame distortion, battery compartment integrity, and potential electrical hazards.

Panel Repair and Replacement: Minor collisions often result in dents, dings, or small panel damages. Skilled technicians use advanced techniques like plastic welding, spot-welding, and precision cutting to repair or replace damaged panels, ensuring a seamless finish and optimal structural strength.

Electrical System Restoration: Tesla vehicles have complex electrical systems that require meticulous attention during the repair process. Technicians must address any issues related to power electronics, battery packs, charging ports, and wiring harnesses to ensure the vehicle’s performance and safety standards are met.

Body Alignment and Paintwork: Precise body alignment is crucial to maintain the vehicle’s structural integrity and aesthetic appeal. Repairs involve realigning panels, straightening frames, and performing meticulous paintwork to match the vehicle’s original finish.

Quality Assurance and Testing: Before a Tesla vehicle is released back to its owner, it undergoes rigorous quality assurance tests. These include safety inspections, performance evaluations, and range checks to ensure the restored vehicle meets Tesla’s high standards.

Historical Context:

Tesla minor collision repair has evolved alongside the rapid growth of electric vehicles. As Tesla’s market share expands, the demand for specialized services to support its unique EV technology also grows. The early days saw ad-hoc solutions and repairs, but over time, standardized procedures and trained professionals have emerged, leading to more consistent and high-quality service.

Significance:

This specialized repair sector is pivotal for several reasons:

Tesla minor collision repair has transcended geographical boundaries, becoming a global phenomenon with varying regional dynamics:

| Region | Key Trends | Challenges |

|---|---|---|

| North America | Leading adoption of Tesla vehicles, resulting in a growing demand for specialized repair services. Established networks of authorized service centers and independent shops cater to this need. | High labor costs and regulatory compliance can impact service pricing, making it a competitive market. |

| Europe | Rapid growth in EV sales, especially in countries like Germany and the UK, has led to increased awareness and demand for Tesla collision repair services. | Strict environmental regulations require precise and eco-friendly practices, adding complexity to repairs. |

| Asia Pacific | China and Japan are witnessing a surge in EV adoption, driving the need for specialized repair facilities. Mobile repair services are gaining popularity due to dense urban populations. | Limited availability of genuine parts and skilled technicians poses challenges in some markets. |

| Latin America | Growing awareness of electric vehicles, particularly in countries like Brazil, where government incentives promote EV sales. | Lack of standardized training programs and limited access to advanced tools can hinder service quality. |

The economic landscape surrounding Tesla minor collision repair is dynamic and multifaceted:

Market Size: The global electric vehicle market is projected to reach USD 734.8 billion by 2027, driven by stringent environmental regulations, government incentives, and advancements in battery technology (Grand View Research, 2022). This growth directly translates to increased demand for collision repair services for Tesla and other EV brands.

Investment Patterns: Auto manufacturers, including Tesla, are investing heavily in building dedicated service networks and training programs to address the skills gap in EV repairs. This trend is expected to continue as the market matures.

Revenue Streams: Specialized collision repair centers can generate revenue through direct repair agreements (DRAs) with auto manufacturers, insurance claims, and direct customer payments. The average cost of a minor collision repair for a Tesla vehicle ranges from $1000 to $3000, depending on the extent of damage.

Economic Impact: According to a study by the International Energy Agency (IEA), EV adoption could reduce global vehicle lifecycle costs by up to 20% due to lower maintenance and energy expenses (IEA, 2021). This economic advantage further underscores the importance of efficient collision repair practices.

Technological innovations play a pivotal role in shaping the future of Tesla minor collision repair:

Advanced Materials: The development of lightweight and durable materials, such as advanced composites and carbon fiber, offers more efficient repair solutions. These materials can be tailored to match the vehicle’s original properties, enhancing structural integrity and performance.

Robotic Repair Systems: Automated robotic arms are being introduced for tasks like panel beating, welding, and paint application. They offer increased precision, consistency, and reduced labor costs, allowing technicians to focus on more complex repairs.

Digital Imaging and CAD Software: 3D imaging and computer-aided design (CAD) software enable detailed digital mapping of vehicle damage, facilitating accurate measurements and repair planning. This technology streamlines the assessment process and improves overall repair quality.

Battery Repair and Recycling: As battery technology evolves, so do the methods for repairing and recycling them. Advanced diagnostics and specialized tools are being developed to identify and rectify issues within EV batteries, extending their lifespan and reducing waste.

Telematics and Remote Diagnostics: Tesla vehicles equipped with telematics systems enable remote monitoring of vehicle health, predictive maintenance, and over-the-air software updates. This technology can aid in collision repair by providing real-time data for more informed decision-making.

The regulatory environment surrounding Tesla minor collision repair is complex and varies across jurisdictions:

Safety Standards: All vehicles, including electric cars, must meet stringent safety standards set by national authorities. These regulations cover structural integrity, electrical systems, and emission control, ensuring that repaired vehicles are safe for operation.

Waste Management and Recycling: Many regions have strict environmental laws governing the disposal and recycling of automotive waste, especially EV batteries. Repairs must adhere to these regulations to minimize environmental impact.

Consumer Protection: Consumer protection laws safeguard the rights of vehicle owners during repairs. These include fair pricing, transparent communication, and warranty coverage for authorized repairs.

Training and Certification: Some countries mandate specific training programs and certifications for technicians performing EV repairs. This ensures a skilled workforce capable of handling the unique challenges of electric vehicles.

Despite its potential, Tesla minor collision repair faces several challenges and criticisms:

Skills Gap: The specialized nature of EV repairs has led to a shortage of trained technicians. Addressing this gap through comprehensive training programs and incentives for skilled workers is essential.

Parts Availability: Genuine EV parts, especially for niche models, can be scarce and expensive. Establishing robust supply chains and encouraging parts recycling can mitigate these issues.

Cost Concerns: Minor collision repairs for EVs may carry a higher price tag due to advanced technology and specialized skills required. Transparent pricing structures and consumer education can help manage expectations.

Environmental Impact of Replacement Parts: The production of new parts contributes to environmental strain. Promoting recycling, remanufacturing, and the use of sustainable materials can reduce this impact.

Proposed Solutions:

Challenge: A leading Tesla service center in the heart of Silicon Valley faced increasing demand for minor collision repairs amidst a skilled labor shortage.

Solution: The center partnered with local community colleges to develop specialized training programs for EV repair technicians. They also invested in advanced robotic systems and digital imaging technology to streamline repairs, reduce costs, and improve efficiency.

Outcome: Within two years, the service center witnessed a 25% increase in minor collision repair volume while maintaining high-quality standards. The partnership with local educational institutions ensured a steady stream of skilled technicians, addressing the labor shortage.

Scenario: Urban congestion and limited parking spaces in Tokyo presented challenges for traditional service centers. Many Tesla owners sought convenient, mobile repair options.

Solution: A Japanese startup launched a mobile collision repair service, equipped with advanced diagnostic tools and a fleet of fully stocked vans. Technicians visit customers’ locations, assess damage, and perform repairs on-site, minimizing downtime for vehicle owners.

Impact: This innovative approach gained popularity among Tesla owners in Tokyo, filling a gap in the market. The mobile service reduced repair times by 30% and received excellent customer reviews for its convenience and efficiency.

The future of Tesla minor collision repair is poised for exciting developments:

Autonomous Repair Robots: Advanced robotics will continue to revolutionize the industry, with fully autonomous robots handling simple repairs like body panel alignment and paintwork. This trend will reduce labor costs and increase repair throughput.

Predictive Maintenance and Remote Diagnostics: As telematics technology evolves, vehicles will be equipped with sensors that can predict maintenance needs, including collision-related repairs. Remote diagnostics will enable technicians to perform virtual assessments, saving time and resources.

3D Printing and Rapid Repairs: 3D printing technology offers the potential for on-demand, customized repair parts, reducing lead times and inventory costs. This method could be particularly useful for rare or hard-to-find components.

Sustainable Repair Practices: There will be a growing emphasis on eco-friendly repair methods, including the use of recycled materials, water-based paints, and energy-efficient equipment. These practices align with the sustainability goals of both Tesla and the automotive industry as a whole.

Global Standardization: The industry is likely to move towards global standardization of training programs, parts sourcing, and repair procedures. This will ensure consistency in service quality across different regions, fostering customer trust and confidence.

Tesla minor collision repair is a dynamic and ever-evolving sector within the automotive industry. It has transcended its initial stages to become a critical component of the electric vehicle ecosystem. As technology advances, regulatory frameworks mature, and consumer expectations grow, the demand for specialized services will continue to rise.

The successful integration of advanced technologies, sustainable practices, and global collaboration will define the future of this field. By addressing challenges through innovation, training, and strategic partnerships, the industry can ensure that Tesla vehicles are repaired efficiently, safely, and in alignment with the brand’s sustainability mission.

As we look ahead, the global automotive landscape will continue to be shaped by electric vehicles, and Tesla minor collision repair will play a pivotal role in ensuring their longevity and safety on the road.

Q: Are Tesla minor collision repairs more expensive than traditional repairs?

A: While initial costs may be higher due to specialized tools and techniques, long-term savings can result from improved efficiency and reduced maintenance for EV batteries and systems.

Q: Can I get my Tesla repaired at any service center?

A: It is recommended to use authorized or certified repair facilities to ensure genuine parts, proper training, and compliance with manufacturer standards. However, in urgent situations, reputable independent shops can also provide temporary solutions.

Q: How do I know if my vehicle needs specialized repair after a collision?

A: If your Tesla has sustained any structural damage, experienced battery-related issues, or had other EV systems affected during a collision, it should be assessed by a qualified technician for specialized repairs.

Q: Are there environmental concerns related to Tesla minor collision repair?

A: Like any automotive repair, there are environmental considerations, especially regarding the disposal of waste and recycling of parts. Reputable repair centers prioritize sustainable practices to minimize these impacts.

Q: Can I learn to perform basic Tesla collision repairs at home?

A: While DIY repairs can save costs, working on electric vehicles requires specialized knowledge and safety precautions. It is strongly advised to seek professional training or consult certified technicians for all but the simplest of repairs.

Tesla minor collision repair involves meticulous processes by trained technicians. Inspection identi…….

Tesla minor collision repair demands meticulous assessment using specialized tools for precise damag…….

Tesla minor collision repair is crucial for preserving structural integrity and aesthetic appeal aft…….

Tesla minor collision repairs focus on fixing small damages to Tesla vehicles using advanced techniq…….

Tesla minor collision repair for trunk and hood misalignment is crucial for both vehicle safety and…….

Tesla minor collision repair involves a meticulous evaluation by certified technicians who inspect e…….

Tesla minor collision repair services efficiently address door dings to more significant body damage…….

Tesla minor collision repairs focus on swift, quality service. Specialized shops use advanced techno…….

Tesla minor collision repair focuses on thorough damage assessment, using advanced techniques like m…….